Mechanical, electrical, and plumbing systems (MEP) today have become a part and parcel of almost all types of building construction work. These systems have immense significance as they help create an indoor environment that remains perfect for human occupation even for the longest of periods. However, MEP installations are consideredto be accountable for around 30% of the budgets in a large number of projects. Fortunately, there are so many ways through which the scale of the MEP systems’ price can be reduced, and that too, without any compromises on the quality and performance at all.

Without smart decisions, it is almost impossible to cut prices and bring betterment to the project. A reputed MEP Consultant in San Francisco can play a vital role in saving water and energy to a significant level through MEP design and allied engineering services. This blog sheds light on how the cost of MEP systems can be reduced or kept under control in a particular building construction project:

- Keep all the concerned parties involved from the very beginning

Poor communication during the construction of a building often leads to so many amendments which result in increased costs. For example, in case the installation requirements and dimensions of any pieces of equipment are assumed randomly, the construction will definitely call for a large number of changes followed by increased cost. The best way to avoid these miscalculations is that you should include all the concerned parties such as equipment suppliers and contractors from the very beginning of the process. It is necessary to have clarity over everything and also to avoid misunderstandings and confusion.

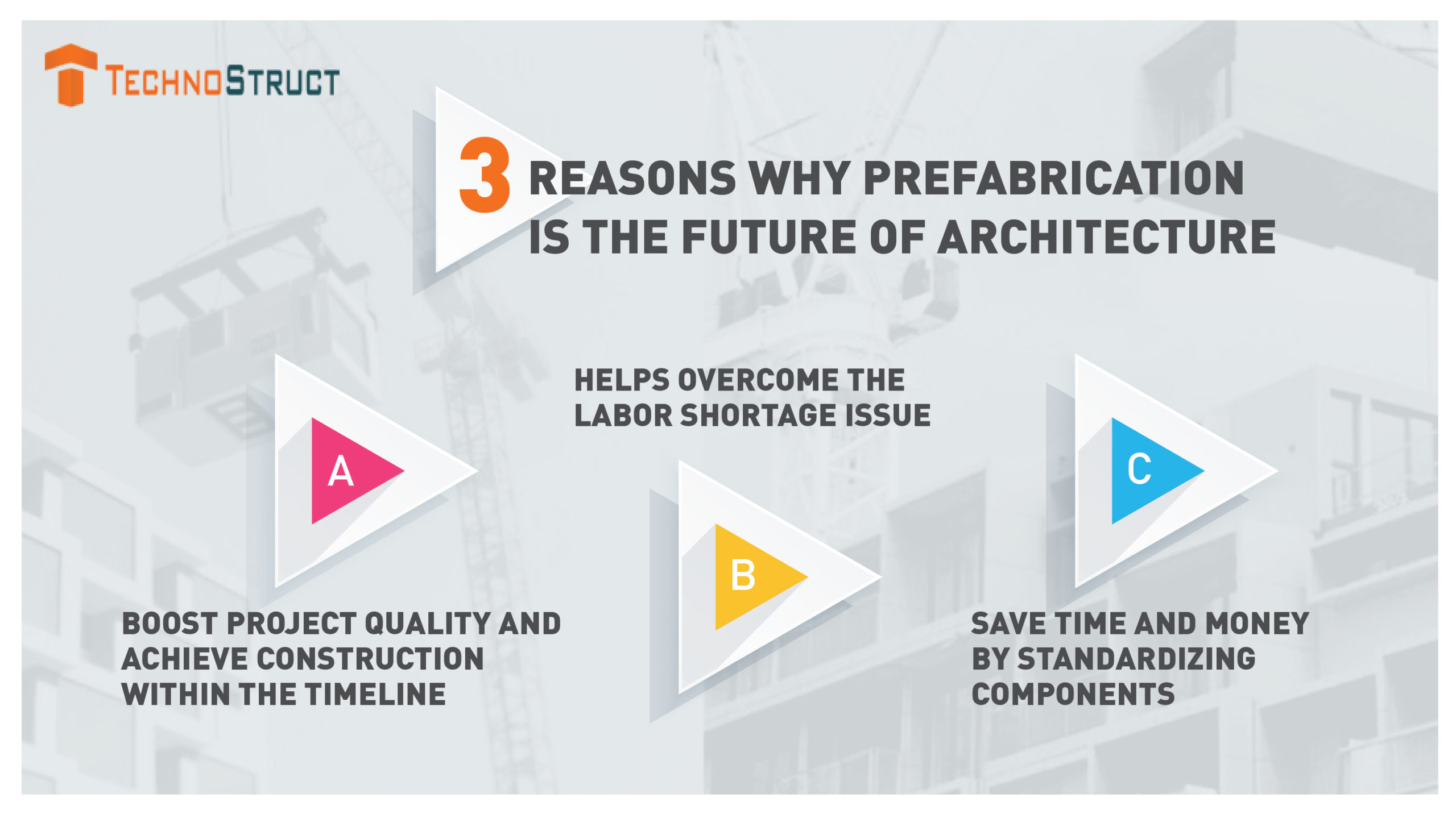

Communication in prefabrication and modular construction plays a significant role. During this phase, the structure is assembled using a large number of prefabricated components to be delivered to the construction site with all the mechanical, electrical, and plumbing systems (MEP) systems built in. This procedure might seem to be quicker but offers lesser flexibility for any type of modifications due to the already completed modules. Therefore, if you keep all the concerned parties involved in the project from the very beginning, you will have to take no amendment call.

- Be particular about the optimization of the MEP installations layout

Mechanical, electrical, and plumbing systems (MEP) installations have so many parts and those that use the most space are often hidden. As an example, a typical commercial building might have hundreds of feet of passage followed by ceilings, piping, and air ducts that are completely hidden behind the walls. Finding an effective, efficient, and cost-effective design using a standard 2D software program can prove to be a Herculean task even for the most competent MEP Consultant in SF and other parts of the country.

However, once the design is created making use of 3D surroundings, the optimization of the MEP systems layout gets easy to accomplish. When you go ahead with an inefficient MEP layout, it will incur two types of major expenses which include an enhanced number of skilled labor and additional construction material. Keeping contractors and equipment suppliers involved matters here also to make the project cost-effective. Once the installation requirements, locations, and dimensions start offering a clearer picture, all the design engineers and architects will be able to better focus on finding the optimal layout.

- A thermal envelope is an effective and efficient way to unload the HVAC systems

The HVAC equipment such as boilers, chillers, and other allied solutions are considered to be the most expensive parts of the mechanical, electrical, and plumbing systems (MEP) installations in any project. However, the prices and scale of these units can be reduced through sufficient brainstorming on their capacities. Typically, it is a popular notion that opting for outsized instrumentality offers great results when it comes to installing HAVC systems across the building or structure to be built. However, oversizing increases the maintenance for sure.

A thermal envelope is an effective and efficient way to unload the HVAC systems. It carries out the conservation of indoor heat during the winter months and prevents the outdoor heat from entering inside during the summer season. In comparison to the building that by code has minimal insulation, a building with effective thermal insulation will offer better and cozy temperatures with a lesser requirement for heating and cooling systems. Over the past few years, the concept of solar power is also getting popular across the world, especially in the countries that receive sunlight for more than 6 months in a calendar year. MEP consultants also remain very specific about it where there is a feasibility of the same.

- Careful planning of the project is all that matters

Apart from various other reasons, the lack of proper planning can also result in a more expensive project regardless of the fact that you have very competent designers, engineers, and experienced contractors. With careful planning, you might need some additional labor when the project is in full swing, and at various times it gets very difficult to get sure-handed labor instantly. In case there are strict deadlines to meet, then you will have to pay overtime to the existing labor involved, making the construction more expensive.

While brainstorming over the planning, you need to consider various seasonal factors. The example of overly busy HVAC installers can be cited here well because, during the peak times of the summers, they often visit your site only at increased prices. Therefore, be it labor, equipment to be used, or any third-party installers, you need to be very specific about all of them while making the plan. If these factors aren’t given serious thought, it would be very difficult for you to achieve the goal of constructing an inexpensive building.

Concluding Remarks

Mechanical, Electrical, and, Plumbing Engineering (MEP) solutions have become the need of the hour for duct, piping, electrical and basic automation in all types of buildings including commercial, residential and industrial. TechnoStruct is one of the fastest emerging names in the field of Design & Construction technology. The core competencies of the company include designing traditional and renewable energy facilities, distribution and substation infrastructure, tenant improvements for office buildings/semi-conductor industry, water pumping, and water/wastewater treatment facilities.

Mechanical, electrical, and plumbing systems (MEP) today have become a part and parcel of almost all types of building construction work. These systems have immense significance as they help create an indoor environment that remains perfect for human occupation even for the longest of periods. However, MEP installations are considered to be accountable for around 30% of the budgets in a large number of projects. Fortunately, there are so many ways through which the scale of the MEP systems’ price can be reduced, and that too, without any compromises on the quality and performance at all.

Without smart decisions, it is almost impossible to cut prices and bring betterment to the project. A reputed MEP Consultant in San Francisco can play a vital role in saving water and energy to a significant level through MEP design and allied engineering services. This blog sheds light on how the cost of MEP systems can be reduced or kept under control in a particular building construction project:

- Keep all the concerned parties involved from the very beginning

Poor communication during the construction of a building often leads to so many amendments which result in increased costs. For example, in case the installation requirements and dimensions of any pieces of equipment are assumed randomly, the construction will definitely call for a large number of changes followed by increased cost. The best way to avoid these miscalculations is that you should include all the concerned parties such as equipment suppliers and contractors from the very beginning of the process. It is necessary to have clarity over everything and also to avoid misunderstandings and confusion.

Communication in prefabrication and modular construction plays a significant role. During this phase, the structure is assembled using a large number of prefabricated components to be delivered to the construction site with all the mechanical, electrical, and plumbing systems (MEP) systems built in. This procedure might seem to be quicker but offers lesser flexibility for any type of modifications due to the already completed modules. Therefore, if you keep all the concerned parties involved in the project from the very beginning, you will have to take no amendment call.

- Be particular about the optimization of the MEP installations layout

Mechanical, electrical, and plumbing systems (MEP) installations have so many parts and those that use the most space are often hidden. As an example, a typical commercial building might have hundreds of feet of passage followed by ceilings, piping, and air ducts that are completely hidden behind the walls. Finding an effective, efficient, and cost-effective design using a standard 2D software program can prove to be a Herculean task even for the most competent MEP Consultant in SF and other parts of the country.

However, once the design is created making use of 3D surroundings, the optimization of the MEP systems layout gets easy to accomplish. When you go ahead with an inefficient MEP layout, it will incur two types of major expenses which include an enhanced number of skilled labor and additional construction material. Keeping contractors and equipment suppliers involved matters here also to make the project cost-effective. Once the installation requirements, locations, and dimensions start offering a clearer picture, all the design engineers and architects will be able to better focus on finding the optimal layout.

- A thermal envelope is an effective and efficient way to unload the HVAC systems

The HVAC equipment such as boilers, chillers, and other allied solutions are considered to be the most expensive parts of the mechanical, electrical, and plumbing systems (MEP) installations in any project. However, the prices and scale of these units can be reduced through sufficient brainstorming on their capacities. Typically, it is a popular notion that opting for outsized instrumentality offers great results when it comes to installing HAVC systems across the building or structure to be built. However, oversizing increases the maintenance for sure.

A thermal envelope is an effective and efficient way to unload the HVAC systems. It carries out the conservation of indoor heat during the winter months and prevents the outdoor heat from entering inside during the summer season. In comparison to the building that by code has minimal insulation, a building with effective thermal insulation will offer better and cozy temperatures with a lesser requirement for heating and cooling systems. Over the past few years, the concept of solar power is also getting popular across the world, especially in the countries that receive sunlight for more than 6 months in a calendar year. MEP consultants also remain very specific about it where there is a feasibility of the same.

- Careful planning of the project is all that matters

Apart from various other reasons, the lack of proper planning can also result in a more expensive project regardless of the fact that you have very competent designers, engineers, and experienced contractors. With careful planning, you might need some additional labor when the project is in full swing, and at various times it gets very difficult to get sure-handed labor instantly. In case there are strict deadlines to meet, then you will have to pay overtime to the existing labor involved, making the construction more expensive.

While brainstorming over the planning, you need to consider various seasonal factors. The example of overly busy HVAC installers can be cited here well because, during the peak times of the summers, they often visit your site only at increased prices. Therefore, be it labor, equipment to be used, or any third-party installers, you need to be very specific about all of them while making the plan. If these factors aren’t given serious thought, it would be very difficult for you to achieve the goal of constructing an inexpensive building.

Concluding Remarks

Mechanical, Electrical, and, Plumbing Engineering (MEP) solutions have become the need of the hour for duct, piping, electrical and basic automation in all types of buildings including commercial, residential and industrial. TechnoStruct is one of the fastest emerging names in the field of Design & Construction technology. The core competencies of the company include designing traditional and renewable energy facilities, distribution and substation infrastructure, tenant improvements for office buildings/semi-conductor industry, water pumping, and water/wastewater treatment facilities.