Time-Bound execution has gained a lot of importance in Construction Industry. It is a source of competitive advantage in many industries and Construction Industry is not an exception either. Earlier, the construction industry had defined roles, the design firms designed, the contractor firms built and the companies stated the requirements; but these lines are blurring by the day and there is a lot of design input from contractors as well as clients. This change has led to over 35% of contractors now having an in-house design engineering team.

A design engineer is a person who is involved in developing conceptual and detailed designs that ensure that a building actually functions, performs and serves its purpose. Thus, with an in-house design team, the design engineers have the freedom to create a series of methodical steps to decide the overall workflow of the project and help deliver the stated objective with resources used optimally. If a design engineer can stick with the following steps, he/she can optimize the speed of the project:

1. Research:

The most valuable element in any project, especially in the construction industry is research. Design engineers must do on-site research and offline research to understand the property or plot allocated for the project. A significant amount of time is spent on collecting the desired information (applicable literature, problems, and successes associated with existing solutions, costs, and marketplace) for taking the design further. Any error on the most primary step can lead to excessive wastage of time at further steps, slowing down the whole project.

2. Design Requirements:

The design requirements are developed based on the client’s requirements and design attributes specifications and functions. The design engineers set out a proper survey to understand and then establish the requirements of the project by conducting a requirement analysis with the civil team and client.

3. Feasibility Assessment:

At this very stage, a design engineer runs an evaluation and analysis of the potential of a project, proposed to support the process of decision making. The feasibility test is run to develop an estimate on the schedule and resources. The purpose of a feasibility assessment is to determine whether the engineer’s project can proceed into the design phase.

The project involves multiple steps that when married together deliver the desired result. Carrying out feasibility test, design requirement study and research collectively leads the whole team to the next phase of a construction project, with minimal or no errors.

4. Conceptualization:

In this phase, a design engineer initiates with developing ideas taking into account the pros and cons of the project. The ideas involve concept and design plan development. Rigorous tests being carried on and off to determine the viability of the project. This leads to minimizing the likelihood of errors, assessing probable risks, evaluate costs and determining the potential success of the intended project. Multiple techniques are used to find a solution against all the odds, like morphological analysis, brainstorming, and synectics. All the ideas then undergo concept evaluation to compare the strengths and weaknesses of possible alternatives.

5. Preliminary Design:

The design concept is far from the detailed design; it can be seen as a skeleton. Preliminary step of designing bridges the gap between design conception and detailed design. The project gets a kick-start if the details are mapped out during the Conceptualization stage. A design engineer tries to align his/her content of work to speed up the process, thus it is always suggested to prepare the plan in advance.

In this task, varying industry to industry, the overall configuration is defined with the use of diagrams, layouts, and schematics.

6. Detailed Design:

As the name suggests, in this design engineering phase, all the W’s and H’s are answered in detail. It may consist of procuring information on materials. This phase further elaborates on each aspect of the project/product by complete description through solid modeling, drawings as well as specifications.

7. Design for Manufacturability:

The art of designing and engineering the building that makes it easy to manufacture is termed as design for manufacturability. The design engineer emphasizes on making the collaborating material requirements, reliability requirements, packaging needs, external surface treatment, design life, maintenance, testability provisions, etc.

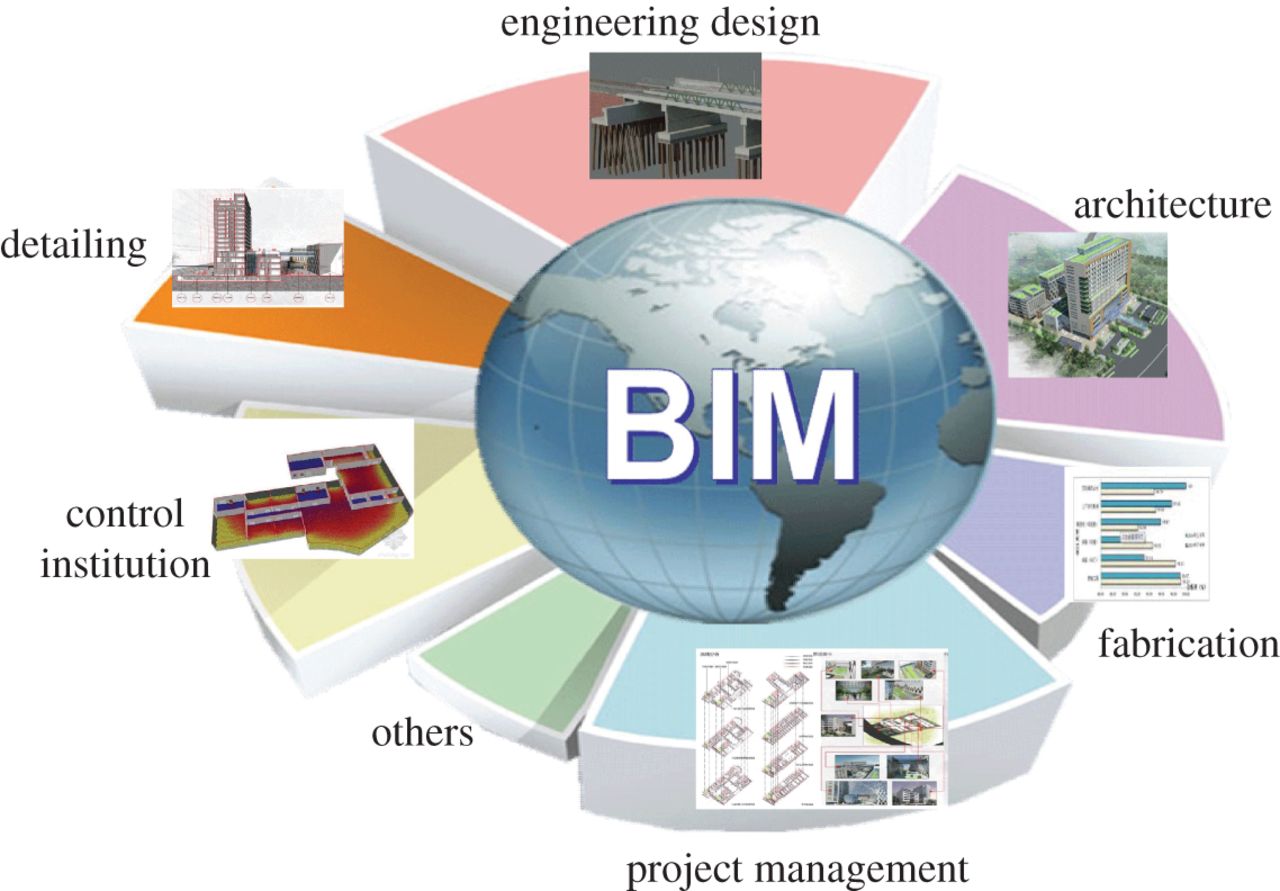

Building Information Modeling (BIM) has made the detailed design phase more effective and efficient. Not just BIM, but Computer-aided design (CAD) programs have helped in optimizing the quality of the design engineering.

8. Construction Planning:

The design engineer has to plan the construction workflow of building a project. At this stage of designing, various steps are taken to pace up the process. The steps include selecting materials, selection of the construction processes, determination of the sequence of operations, and selection of tools such as jigs, fixtures, metal cutting, and metal or plastics forming tools.

Conclusion:

The involvement of various departments can lead to deceleration of the project. The design engineer has to work in tandem with the various managers to coordinate challenges and simultaneously fixing any gap. Meeting deadline in a construction industry is difficult, but not impossible. Factors like weather, government, economic policies, etc. cannot be controlled, while a contingency plan should be in place that can affect the construction design or policy.

TechnoStruct specializes in engineering and design industrial, commercial, high-tech manufacturing, co-generation, solar power, and water infrastructure projects. TechnoStruct has a hold in technology and has a diversified range of services available, apart from BIM, like MEP engineering and design, Mechanical Subcontractor, Solar, Electrical Subcontractor, and many more.