The construction industry is undergoing a major transformation. A new technology called 3D printed concrete, used to manufacture 3D printed concrete homes, is driving this change.

3D printing, also known as additive manufacturing, uses digital models to create 3D objects. Scientists at the Massachusetts Institute of Technology (MIT) first discovered the technology in 1993 as 3DP.

3D printing is done to build the structure by passing the cement mixture through the nozzle and by putting it up in layers.

This technology is not just a novel idea but a practical solution worldwide. We will explore how 3D printed concrete houses are changing the construction industry in the following sections.

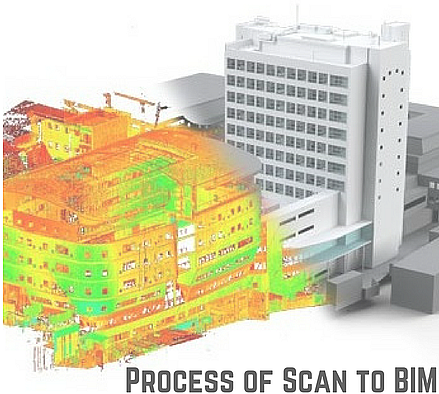

Process Involved in Building 3D Printed Concrete House

Here is an overview of the key steps involved in constructing a 3D printed concrete house:

- Preparation and Setup: The construction site is prepared, and the 3D house printer, such as the Autonomous Robotic Construction System (ARCS), is set up. The printer is positioned to begin the printing process.

- Printing Process: The 3D printer lays concrete layer by layer, starting with the foundation and then proceeding to create the interior and exterior walls of the house. The printer follows pre-programmed instructions based on a blueprint or CAD drawing.

- Layering and Structural Integrity: Each layer of concrete is approximately three-quarters of an inch thick, and the printer adds around 150 layers to create a standard 9-foot wall. The layers are added sequentially, with a set time between each layer, to ensure structural integrity.

- Customization and Aesthetics: The 3D printing process allows for customization in terms of the nozzle design, which can impact the aesthetic finish of the walls. Different nozzle types can create variations in the appearance of the concrete walls, offering options for structural or decorative purposes.

- Post-Printing Installation: Once the basic structure of the house is printed, additional components such as windows, doors, plumbing, and electrical systems are installed manually. These finishing touches are added after the completion of the 3D printing process.

- Strength and Durability: The use of concrete in 3D printing ensures that the house is strong and durable, exceeding the strength of conventional wood-frame constructions. The concrete used in 3D printing is typically two to three times stronger than traditional brick and block homes.

- Cost and Time Efficiency: 3D printed houses offer significant cost and time savings compared to conventional construction methods. The automated printing process reduces construction waste, lowers overall costs, and speeds up the building process, making these homes more accessible and affordable.

Advantages of Building 3D Printed Concrete Houses

Here are the advantages that highlight the potential of 3D printed concrete houses in revolutionizing the construction industry.

- Speed: 3D printing significantly accelerates the construction process. For instance, the Fibonacci House in British Columbia was built off-site in just 11 days.

- Cost-Efficiency: The reduction in labor costs and material waste contributes to these savings. The first 3D house built by Habitat for Humanity in Virginia, for example, took only 28 hours to print the concrete walls.

- Complex Geometry: 3D printing allows for the creation of complex architectural designs that would be challenging to achieve with traditional methods. The Tecla House in Ravenna, Italy, is a prime example of this.

- Sustainability: It reduces material waste and allows for the use of eco-friendly construction materials. The House 1.0, designed by SAGA Space Architects, is an example of a 3D printed house that uses sustainable materials.

Conclusion

3D printed concrete houses are not just a futuristic concept but a practical solution being implemented globally. Discover the future of construction at TechnoStruct.com, where innovation meets practicality.

FAQs

What makes 3D printed concrete special?

3D printed concrete contains all ingredients of a conventional concrete mix but excludes coarse aggregates or crushed stones.

How much does a 3D printed house cost?

Starting at about $10,000, a basic one-bedroom house can get more expensive the more space and complexity you want.

What are the main ingredients of 3D print material (concrete)?

The main ingredients of 3D print material are cement, sand, water, and some additives that account for 10 to 15 percent of the mix design.