The AEC (architectural, engineering and construction) space is progressing with so many advancements in technology and the way construction processes work. The efficiency has improved and time to project has cut down because of better collaboration and execution techniques. In construction, the adoption of technology has not been limited to the software of tools used, but also in every work process like Mechanical Engineering and Plumbing (MEP) designs and services. The construction industry trends suggest that the industry-wide technology investment has grown to $10 billion in less than a year, and is expected to grow multi-fold in the coming years, especially in Prefabricated MEP.

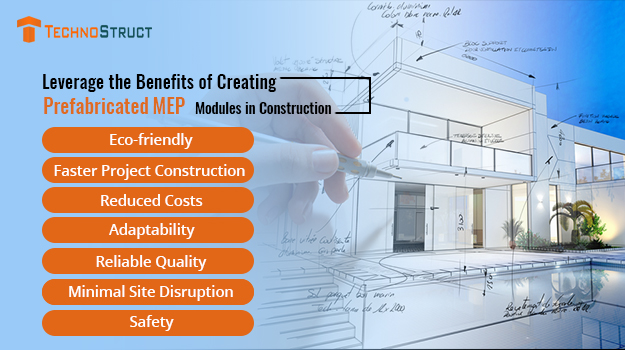

The MEP sector has been complex with the creation of its precise drawings and implementation, but the application & integration of prefabrication in the process has added a greater scope for efficiency. Drawing an MEP system modular using prefabrication method involves accurate coordination and collaboration, and establishing connection methods is imperative between modules to assemble it in a workshop for easy transport and installation. Here are a few benefits that will motivate the construction industry to leverage prefabricated MEP:

Eco-friendly: At any construction site, there is a lot of wastage of material, but as the designing and development will happen in a controlled environment (factory or workshop), the extra materials can be recycled in-house instead of sending it in the garbage, making it an eco-friendly and energy efficient practice. As the construction will also till maximum accuracy, the joints will be tighter and the air filtration in the building will enhanced, enabling more effective wall insulation and increased energy efficiency.

Faster Project Construction: Working in a controlled environment will eliminate any on-site disruption and allow the planning to flow in an effective way and build the prefabricated MEP structure at a much faster rate. The overall time saving sometimes goes up to 50 percent to conventional building methods, according to some studies. Also, as multiple MEP modules are created at the same time the chances of construction delays also negate. Prefabrication can begin off site early, without waiting for MEP clearance from the civil team.

Reduced Costs: In a prefabrication construction environment, there is less labour requirement, less material wastage, and also as the construction can be tailored- the construction costs reduce big time.

Adaptability: Prefabricated structures are built at a factory site and relocated and assembled at the construction site which allows the AEC experts to reach and access points where it is difficult to reach. This offers experts the flexibility to construct and fit at their convenience without hampering the design process of the building.

Reliable Quality: The material that is used for prefabricated structures and the environment they are built-in are constant which allows establishing uniform quality throughout. Experienced professionals and weather resistant factory and multiple quality checks contribute to the manufacture of reliable modules.

Minimal Site Disruption: Mechanical, engineering and plumbing are a major part to make an infrastructure operation in any way, and to take away the who part of it to a factory workshop will reduce on-site traffic and only required professionals will stay associated. There will be lesser noise pollution, no waste collection at site and lesser people to disrupt the work process, which will enhance the work productivity.

Safety: To construct prefabricated MEP modules a weather controlled environment is used which reduces problems related to moisture, environmental hazards and dirt. This further protects the workers from being exposed to health risks, changing weather and also reduces the chances of fatal incidents.

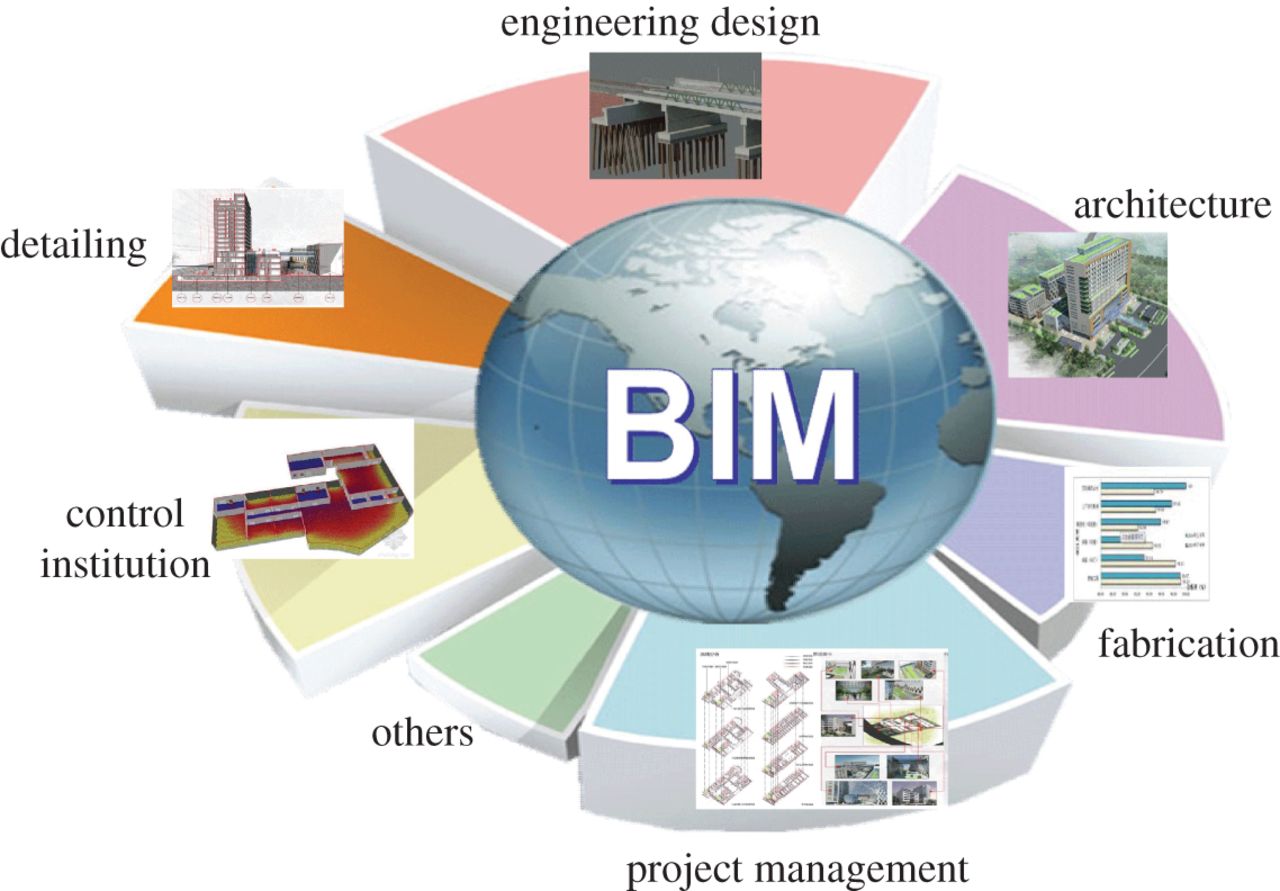

TechnoStruct LLP is a leading name in the architecture, engineering and construction industry. It specializes in providing mechanical and engineering solutions, designing, solar engineering solutions, and construction solutions to commercial projects across industries, with a diversified range of services including but not limited to BIM, MEP engineering and designs, Mechanical Subcontractor, Solar, Electrical Subcontractor, and many more.