Imagining a technologyless 2025 is impossible. Technology has become an integral part of the modern world, and the construction industry is also experiencing its positive impacts. 3D scanning or 3D laser scanning has transformed the way data is collected, processed, and analyzed for construction projects.

3D scanning technology has been in use since the 1960s, and large systems were used to digitally copy objects. As computers evolved, AEC professionals started using small and affordable devices to recreate objects digitally. In this blog, get familiar with 3D scanning technology and its future trends in construction.

Introduction – 3D Scanning

3D laser scanning is a cutting-edge technology that facilitates digitally capturing environments or objects in accurate dimensions and shapes. This technology creates an accurate 3D simulation, gauging the distance between the scanner and the object through laser beams.

It creates a digital model by emitting laser beams that bounce off the surface and return to the scanner. 3D scanning is popular in various industries such as engineering, construction, architecture, and manufacturing.

Top Future Trends in 3D Scanning Technology

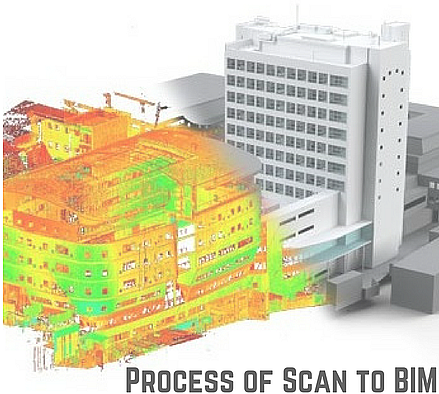

Integration with BIM

3D laser scanning is being integrated with BIM (Building Information Modeling), and this trend will continue in the future to streamline construction projects. AEC professionals can import the scanned data into BIM software to boost precision and coordination among stakeholders.

The combination of these two remarkable technologies ensures better project visualization, clash detection, and lifecycle management. Additionally, it helps reduce rework and improve collaboration. In the future, evolved cloud-based BIM platforms will make it easy to remotely share and analyze the 3D scanned data.

Drone-Based 3D Scanning

To scan large or complex construction sites, drones equipped with LiDAR or photogrammetric tools are being used. Leveraging this method assists in capturing high-quality data from large areas with minimal manpower. It helps reduce the survey costs and time.

Drone-based scanning particularly excels in infrastructure inspection, topographic mapping, and progress monitoring. In the future, there may be a relaxation in drone regulations, and automation will also improve, it will enable the construction industry to use drones more for site scanning and providing the latest models of evolving sites.

Mobile-Based and Handheld Scanners

Allowing flexible and quick data capture, mobile and handheld 3D scanning technology is gaining popularity in the industry. Characteristics of these devices, such as compactness, capability to scan even hard-to-reach areas, and affordability, make them suitable for inspections, retrofitting, and progress monitoring.

With this level of ease and portability on offer, more field workers will be able to collect data even though they do not have specialized training. Additionally, project managers will be able to reduce communication gaps between them and site teams, and more precise site documentation will follow.

Real-Time 3D Scanning and Feedback

Real-time 3D scanning facilitates quick visualization and site analysis. Teams can get instantly alerted by this technology about the difference between design plans and as-built, and prevent costly errors. Moreover, AI and edge computing allow the processing of scanned data on-site with lower latency.

A quick feedback loop paves the way for faster project management, decreases downtime, and increases quality control. In the future, supervisors will use real-time scanning to ensure continuous alignment with project specifications.

Scan Data Analysis with AI and Machine Learning

Another exciting future trend that will follow soon is the interpretation of 3D scan data with AI and machine learning. It will assist in automatically learning about structural components, deviations from plans, and anomalies. This way, professionals will not have to dedicate a high amount of time for manual inspection and they will be able to enhance the precision of defect detection.

For example, misalignments, cracks, or missing elements can be highlighted by AI algorithms directly from the scan data. Growing datasets will cause the emergence of predictive analysis, enabling professionals to predict issues before they occur.

Cloud-Based 3D Scan Data Management

Cloud platforms have disrupted the process of storing, sharing, and analyzing scanned data. Teams working in the field can upload scans to the cloud, and other teams can access them anytime and anywhere, which fosters collaboration. Features such as measurement tools, in-built viewers, and annotation are available on many cloud-based platforms.

It is also possible to integrate cloud tools with BIM and project management software, leading to faster decision–making, higher transparency, and data security. Future advancements in storage and bandwidth technology will allow cloud systems to become an integral part of the AEC industry.

4D and 5D Construction Modeling

Data obtained through 3D scanning will be integrated more into 4D and 5D construction models. As a result, along with visualizing structures, project teams will experience ease in tracking financial impact and schedule progress in real-time.

The addition of 4D and 5D BIM with 3D scan data is ideal for promoting better project forecasting, risk assessment, and scenario planning. It will also help in making informed decisions. Hence, it is a holistic approach, which is essential for fostering efficiency in project delivery and budget control.

SLAM Technology Increasing Precision

Real-time mapping of environments while tracking the movement of a scanner is easy with Simultaneous Localization and Mapping (SLAM). Thus, mobile devices for 3D scanning can demonstrate higher accuracy and usability and prove suitable for indoor areas such as multi-story buildings or tunnels.

Moreover, using SLAM facilitates seamless data capture even in GPS-restricted areas. Hence, an evolution in SLAM algorithms will help in rapid scans with minimal drift. Professionals may utilize it for a wide array of projects every day.

Lifecycle Management and Sustainability

3D scanning is essential for allowing effective material planning, optimizing renovations and retrofits, and lowering waste, which is crucial for sustainable construction. The scans help assess energy performance, aid facility management, and monitor material degradation.

Scan data will also play a significant role in sustainability planning with integration into lifecycle digital twins. This technology will pave the way for acquiring certifications such as BREEAM or LEED, as environmental regulations become stricter.

Robotic Automation for 3D Scanning

Companies are developing autonomous robots for continuously monitoring construction sites using 3D scanners. The standout features of these robots are their ability to navigate complex terrain and regularly collect data. Consistent and repeatable results are ensured with robotic scanning, leading to quality assurance and documentation.

With the evolution of robot mobility and AI navigation, robots will aid in site progress monitoring more, especially in areas where humans cannot enter or may face health issues. AEC firms can deploy robots for 3D scanning to cut labor costs and promote safety on-site.

Final Thoughts

Continuous advancement in 3D scanning technology will make it an indispensable asset for construction firms in the future. This technology can integrate easily with BIM and other essential construction tools, which will further grow its impact on the industry. Embrace this new addition to the construction process and cultivate better results with improved speed, precision, and efficiency in your workflows.

FAQs

Q 1: What technology is used in 3D scanning?

Ans: Lasers are equipped in most 3D scanners, and they function through a process called ‘trigonometric triangulation.’ 3D scanners show two or more lasers at a point on an object, and one or more sensors capture the angles of the beams which are reflected.

Q 2: What are the benefits of 3D scanning?

Ans: A few advantages of this technology are faster data capturing, high precision, visualization, clash detection, and non-contact technology.

Q 3: What are the disadvantages of 3D scanning?

Ans: Some of the disadvantages of 3D laser scanning are as follows:

- Complex learning curve.

- High costs

- Limited range.

- Large data files.

- Limitations due to the environment.